By-DR.VANITA PRASAD

FOUNDER, DIRECTOR & CTO – REVY ENVIRONMENTAL SOLUTIONS PVT. LTD.

Dr.Vanita Prasad – a scientist turned into an Entrepreneur, is a New Age Environmental Instrumentalist providing Biotech solutions. Having done her Ph.D. in Environmental Biotechnology and with her extensive experience of 28 years in waste bioremediation with various academic and Industrial institutions, she floated her own company REVY Environmental Solutions Pvt. Ltd. with a vision to solve the global crisis of food, water, and energy and to make our mother earth cleaner and greener. Her mission is to strive for innovation and provide economically feasible, eco-friendly & sustainable solution to the world.

She is leading this company as a Founder, Director and CTO. Her core expertise is in anaerobic digestion technology and innovation of customized Bio-cultures. At REVY, they have developed an indigenous product Granulated Sludge, a micro flora of carefully chosen and embedded Anaerobic Bacteria, an innovation that act as a very cost effective solution for High rate Anaerobic Digesters for its commissioning as well as work as a medicine for many sick units of STPs & ETPs. She is now focusing on developing a biological process of Biohythane production: Next generation Clean and Renewable Energy to be used as Future Fuel.

She is a DBT – BIRAC – BIG & SPARSH Grantee and holds various patents for specific innovation in the field of Waste management and Renewable energy (Bio hydrogen and Bio methane).She herself and her company has won many awards and accolades at National and International forums for the work being recognised as Low energy, cost effective and sustainable solutions for waste / wastewater treatment.

To name some of these awards are –

- BRICS Mulan Award, by BRICS China under BRICS Women’s Business Alliance Initiative;

- Winner of India-Israel Innovation Challenge 2017 organized by Invest India;

- Winner of “ICONIC WOMEN LEADER AWARD” by ASIA – GCC Conclave;

- BIRAC-TiE WInER Award 2019 by DST, GOI.

- Finalist for ‘Women in Biogas’ Award By World Biogas Association in 2022

COMPANY PROFILE:

REVY Environmental Solutions Pvt. Ltd. is established in 2017 and is a DPIIT recognized start up supported by BIRAC, Social Alpha, Venture Centre and Savli Technology and Bio Incubator. REVY provides Economical and Sustainable Solutions for Waste/Wastewater Treatment by providing its products (innovative Bacterial Consortia) and services (a specialized app called R-EMAPP).

REVY has developed a process for development of ‘Anaerobic Granulated Sludge’, ‘Aerobic Biomass’ as well as ‘Biomass Growth Enhancement Formulations (BGEF)’ for Both Anaerobic as well as Aerobic processes. REVY’s Seed Biomass will support faster start of aerobic / anaerobic reactor as well as quick solution for any ailing unit. Their Granulated Sludge can withstand higher loading rate. It has a capability to reduce higher COD/BOD load while giving better biogas yield in comparison to flocculent systems. BGEFs have been developed keeping in view the nutritional requirement of the biomass to remain healthy and active (through continuous enhancement of MLVSS). These formulations have been researched to provide desired result in the lowest possible dosage.

To support this product application and to create a better user experience the company has developed an App, called R-EMAPP which helps in tracking day to day performance of these biologicals’ reactors remotely.

REVY as a firm has achieved various awards. Below are the list of some of them:

- Winner of Sankalp x Artha Global Impact Awards 2023

- Winner of World Biogas Association Awards under Best Anaerobic Digestion/Biogas Support Service O&M company 2023 under environmental Biotechnology company

- Winner of ‘Innovation Agora Pod Recognition’ Programme” announced at India Energy Forum by CERAWeek & IHSMarkit. Invited to present our Clean Energy solution at CERAWeek Houston in Mar’22

- Winner of National Start Up Awards 2021 under environmental Biotechnology company

- Awarded as ‘ Frontrunner’ in Cleantech sector by ITC Go Global Awards 2021

- REVY Conferred Global Technology Innovation Award in MSME Category by GITA in 2022

- Startup winner award of Amrut -2.0 in 2022

- Winner of “Swachch Bharat Grand Challenge” organized by Start-up India in 2019

- Winner of Social Alpha Urban Liveability Challenge,2019 under Cleantech category

- Winner of “Integrate to Innovate Challenge” organized by Invest India in 2019

- Winner of YESSCALE under cleantech category and is being funded by Villgro in 2019

CASE STUDY

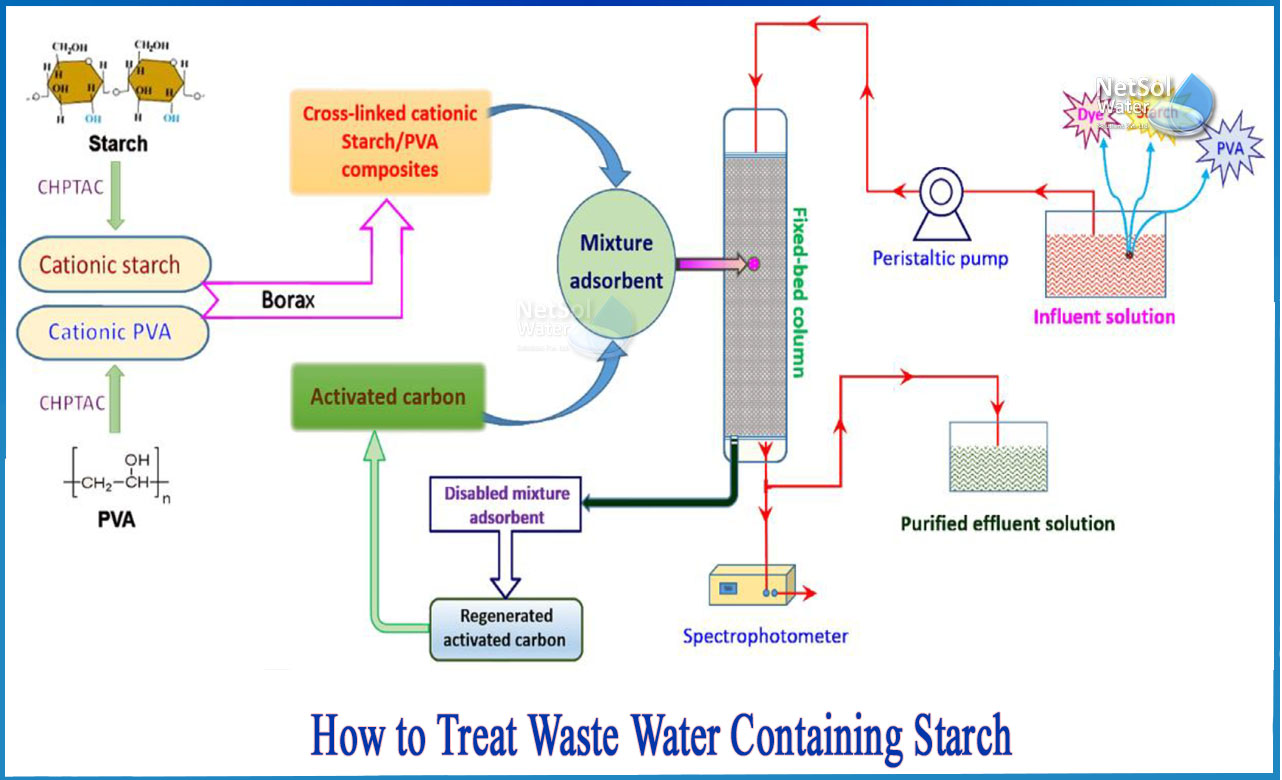

A potato Starch manufacturing industry at Gujarat generates large quantities of waste water containing considerably high COD (25000 -35000 mg/L) mainly in form of starch, glucose and protein from Potato Crush and a TSS of about 10,000 mg/L. The TSS is in form of fine particles of left over potato skin. Waste water should have a high BOD due to high biodegradable content, hence can be treated using biological methods in order to enable an environmentally safe utilization or disposal. The growing quantities of wastewater generated in the industry require innovative treatment processes that are capable of achieving significant cuts in cost of treatment. Technologies that combine efficient COD & BOD reduction along with TSS removal capability, the production of reusable waste water at competitive costs represent the most desirable solutions.

Anaerobic treatment of this effluent having high content of biodegradable material is broken down by microorganisms in absence of air and Biogas is produced. This process is popular because it is energy positive, requires less foot print and produces very little biomass. But the major problems associated with potato waste include easy degradability resulting in acidification which rapidly lowers the pH noticeably. This problem is associated with low pH of the substrate itself, poor buffering capacity and the possibility of potentially high volatile fatty acid (VFA) accumulation during digestion.

Anaerobic digestion is the standard technique to treat wastewater to reduce the amount of organic matter. To establish that use of REVY’s anaerobic biomass consortia and Biomass Growth Enhancement Formulations (BGEFs) which can help reduce organic content and stabilize UASB reactor performance. a treatability Study was conducted to establish most optimum treatment scheme for effluent so that treated water to meets statutory disposal / reuse norms.

| Sr. No. | Parameters | Clear water | Settled Sludge | Unit |

| 1. | pH | 6.44 | 4.64 | — |

| 2. | Conductivity | 18 | ND | mƱ |

| 3. | Total Dissolved Solid | 12300 | ND | mg/L |

| 4. | Total Suspended Solids | 155 | ND | mg/L |

| 5. | Total Solids | 2.1 | 4.34 | % |

| 6. | Total Volatile solids | 1.3 | 3.52 | % |

| 7. | Volatile Suspended Solids | 103 | ND | mg/L |

| 8. | BOD | 17500 | 62500 | mg/L |

| 9. | COD | 25661 | 94180 | mg/L |

| 10. | VFA | 5735 | 14605 | mg/L |

| 11. | Alkalinity | 4050 | 3000 | mg/L |

| 12. | Ammonia | 1204 | 420 | mg/L |

| ND- Not Done | ||||

Clear water and Settled Sludge was collected from industry and analysed to identify the properties of the same. Anaerobic treatment was done in lab scale UASB reactors. Results of experiment with low and high loading rate are tabulated. 77% COD reduction was achieved at high loading rate yielding 5.7 Litre gas per day. On basis of this, it is implemented on full scale treatment plant treating 400 m3/d effluents daily which will produce 4500 m3 gas per day containing 64-68 % methane gas.

| Sr. No. | Parameters | Higher loading rate | Lower loading rate | Units |

| 1 | VFA | 59 | 56 | % |

| 2 | TSS | 73 | 76 | % |

| 3 | VSS | 77 | 79 | % |

| 4 | COD | 77 | 68 | % |

| 5 | BOD | 69 | 60 | % |

| 6 | Gas Volume | 5.7 | 3.2 | L/d |

Liquid wastewater anaerobic treatment Solids from wastewater primary treatment

| Sr. No. | Parameters | Value | Units |

| 1 | Wastewater volume | 400 | m3/d |

| 2 | COD of wastewater | 30000 | mg/L |

| 3 | COD load | 12000 | kg/d |

| 4 | Methane generation | 3000 | m3/d |

| Sr. No. | Parameters | Value | Units |

| 1 | Wastewater volume | 400 | m3/d |

| 2 | Solids | 1 | % |

| 3 | Total Solids | 4000 | kg/d |

| 4 | Proposed treatment | Anaerobic CSTR | – |

| 5. | Estimated Methane | 1850 | m3/d |

The results obtained during this study will account for saving 55.4 tons of GHG emissions per day and annually 20220 tons from effluent treatment whereas from solid waste treatment, 34.6 tons of GHG emissions per day and annually 12640 tons will be saved.

To summarize we can say anaerobic treatment of effluent and solid waste using REVY-S will offer an alternative solution which is eco-friendly and economical as it can produces 9 MWh electricity per day (renewable energy) while treating the waste and resulting in climate protection through an improvement in the CO2 balance of the treatment plant.